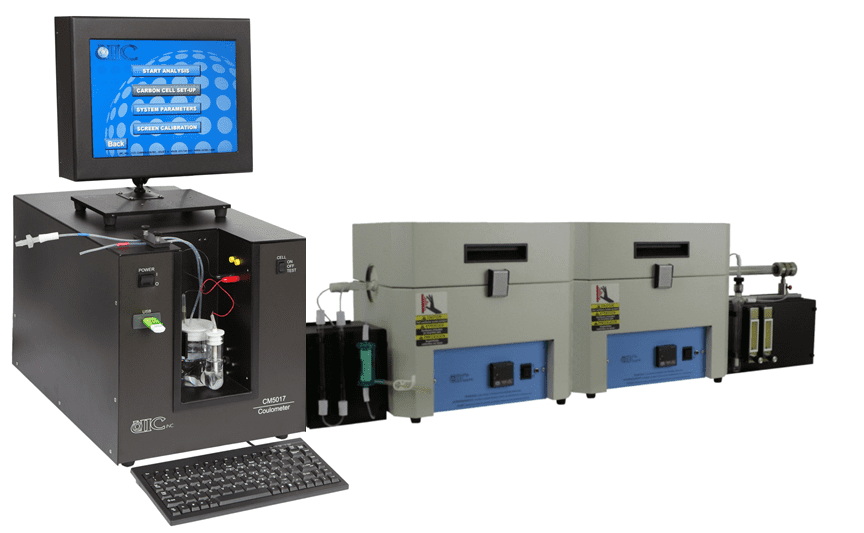

CM320 Total Sulfur Analyzer

The CM320 Total Sulfur Analyzer is a complete analytical system allowing the direct measurement of total sulfur in a wide variety of sample matrices and concentrations. The CM320 consists of a dual zone, high temperature furnace and a sulfur coulometer. The CM320 easily handles solid or liquid samples with concentrations from ppm levels to 100% without user calibration. UIC’s analyzers are rugged, accurate and adaptable to most applications. They are used extensively in industrial, research and educational laboratories worldwide. TheCM320 system includes the following components pictured above:

CM5017S SO2 Analyzer

| CM5380 Dual Zone Furnace with CM5382 Sample Introduction Kit

|

Instrument Capabilities

A major advantage of the CM320 Total Sulfur Analyzer is the use of coulometric detection. Employing the principles of Faraday’s Law, the CM5017S SO2/H2S Analyzer automatically measures the absolute mass amount of sulfur dioxide and/or hydrogen sulfide evolved from a combusted sample. No user-calibration is required and linear detection is available from less than 1 µg sulfur to over 10,000 µg sulfur. Using this 100% efficient coulometric process, relative standard deviations of 0.2% or better are common for standard reference materials. For smaller concentrations, an absolute deviation of approximately 1 µg S is typical.

Sample sizes can range from 0.5 mg to 10 grams with concentrations from 1ppm to 100%.Analysis times of 5-7 minutes are typical.

Total Sulfur

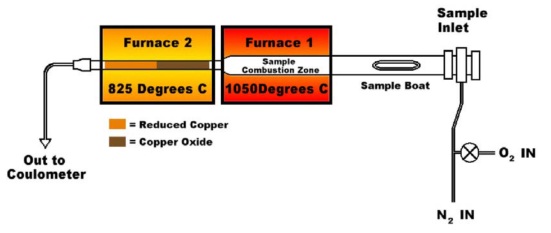

Samples are weighed into a ceramic combustion boat, covered with a vanadium pentoxide or tungsten trioxide accelerator, and transferred into the combustion furnace at 1050ºC. The sample, in the presence of the accelerator and added oxygen, combusts to form SO2 in equilibrium with SO3. This mixture is then conveyed by the nitrogen carrier gas into a second furnace at 825ºC and passed over reduced copper, quantitatively converting all SO3 to SO2, which is subsequently conveyed to the coulometric cell of the detector. There, the resulting sulfur dioxide and/or hydrogen sulfide is automatically measured using absolute coulometric titration.

Data Handling

Names, weights, volumes or areas of up to 50 samples can be entered, to be used by the CM5017S in calculating the final result. Analytical progress is digitally displayed in user-selectable units. A detailed report is printed while each sample is running that includes the final result. The results can also be stored on USB Flash Drive for further data handling.

Ordering Information

CM320 – Total Sulfur Analyzer

Includes: CM5017S SO2 Coulometer, CM5380 Dual Zone Furnace, and CM5382 Sample Introduction Kit with tools and accessories for the analysis of solid samples. (P/N CM320-01 110V, 50/60Hz) (P/NCM320-02 220V, 50/60Hz)

Optional Equipment:

CM5390 Automated Boat Inlet – Automates the sample purge and introduction/withdrawal cycles of the sample combustion process. See the CM5390 specification sheet for more details.

.