CM180 Surface Carbon Analysis By High Temperature Oxidation And Coulometric Detection

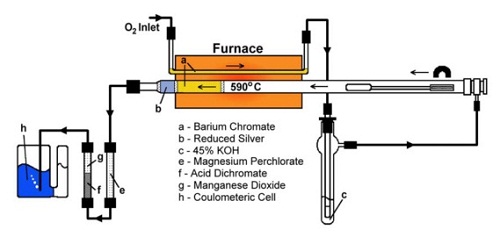

The CM180 Surface Carbon Analyzer is a complete analytical system capable of measuring the surface carbon on a wide variety of non-combustible materials including metals and glass. Combining a high-temperature oxidation furnace and a highly sensitive CO2 detector, the CM180 provides a direct measurement of surface carbon levels without the need for calibration using difficult-to-obtain surface carbon “standards”. The CM180 system includes the following components pictured above:

CM5017 CO2 Coulometer

| CM5300 Horizontal Furnace with CM5322 and CM5324 Furnace Kits

|

Instrument Capabilities

A major advantage of the CM180 Surface Carbon Analyzer is the use of coulometric detection. Employing the principles of Faraday’s Law, the CM5017 CO2 Coulometer automatically measures the absolute mass amount of carbon dioxide resulting from sample combustion. No user-calibration is required and linear detection is available from less than 1 µg carbon to over 10,000 µg carbon. Using this 100% efficient coulometric process, relative standard deviations of 0.2% or better are common for samples containing 1000 to 3000 µg C. For smaller concentrations, an absolute deviation of approximately 1 µg C is typical.

Oxidation times vary with sample type and temperature although 10 to 15 minute analyses are typical.

Surface Carbon

Prior to analysis, the furnace temperature is selected based on the characteristics of a particular sample type and the form of the carbon which is to be analyzed (organic or non-organic). Samples are then introduced into the pure oxygen atmosphere within the furnace where the carbon is oxidized to form CO2. Interfering reaction products (including sulfur oxides, halides, water and nitrous oxides) are removed by the post-combustion scrubbers. The resulting carbon dioxide is then swept into the CM5017 CO2 Coulometer where it is automatically measured using absolute coulometric titration.

Typically, samples are placed within a large porcelain boat and are introduced and withdrawn from the furnace via the manipulator rod.

Data Handling

Names, weights and sizes of up to 50 samples can be entered, to be used by the CM5017 in calculating the final result. Analytical progress is displayed on the 10” LCD touch screen in user-selectable units. Detailed analysis information is automatically saved to an on-board SD card after each sample. Data can also be transmitted through the standard serial and Ethernet ports to be captured on a personal computer or LIMS. In addition, a detailed report can be printed to the optional small format printer while each sample is running.

Ordering Information

CM180 – Surface Carbon Analyzer

Includes: CM5017 CO2 Coulometer, CM5300 Horizontal Furnace, and CM5322 and CM5324

Furnace Kits with tools and accessories for the analysis of samples. (P/N CM180-01 110V,

50/60Hz) (P/N CM180-02 220V, 50/60Hz)

Optional Equipment:

Printer – 3” format impact printer. Includes cable, power supply, paper and ribbon. (P/N CM124078)

CM5390 Automated Boat Inlet – Automates the sample purge and introduction/withdrawal cycles

of the sample combustion process. See the CM5390 specification sheet for more details.